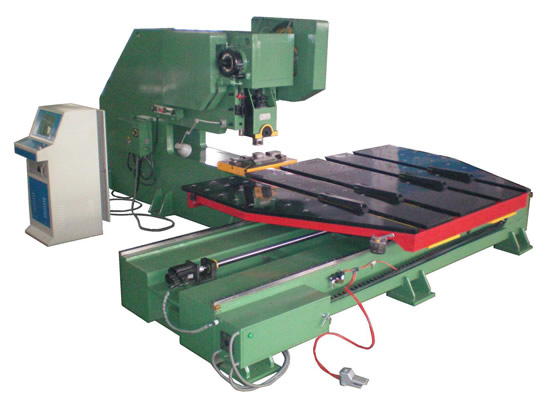

1、改善工艺、模具和作业方法,完成人手模外作业,比方选用冲压机械手作业就可以避免这些问题。关于大批量出产作业,这些冲压机械手不仅能保证冲压作业员的安全,而且能大大进步出产功率,这是冲压技能的发展方向。小批量、多种类的冲压出产,当前难于完成自动化,妥善的方法是尽量选用安全、劳动强度较小、运用方便的东西,使操作更为安全。

2、改造冲压设备,进步出产安全可靠性。现在许多陈腐冲压设备的操作体系、电器控制体系存在许多不安全要素,若持续运用对应其进行技能改造,保证冲压设备的安全可靠性。

3、设备防护设备。因为出产批量小,在既不以完成自动化,又不能运用安全冲压东西的冲压作业中,必须设备安全防护设备,以避免因为操作失误而形成的伤害事故。

1. improve the process, mold and operation mode to achieve manual operation outside the mold, such as the use of stamping manipulator can avoid these problems. For mass production operations, these punching manipulator can not only guarantee the safety of the punching operator, but also greatly improve the production efficiency. This is the development direction of stamping technology. The stamping production of small batch and variety is difficult to realize automation at present. The proper way is to use the tools of safety, less labor intensity and easy to use, so that the operation is more safe.

2. transformation of stamping equipment, improve production safety and reliability. At present, many old stamping equipment control system and electrical control system have many unsafe factors. If we continue to use the corresponding technical transformation to ensure the safety and reliability of the stamping equipment.

3. Installation of protective devices. Because of the small production volume, the safety protection device must be installed in the stamping operation which does not realize automation and can not use the safety stamping tool to prevent the damage caused by the operation error.